Introduction:

In recent years, 3D printing has emerged as a groundbreaking technology that has revolutionized the manufacturing and design industries. This innovative process, also known as additive manufacturing, has the ability to create three-dimensional objects by layering materials one on top of another. With its immense potential, 3D printing is transforming traditional manufacturing methods, empowering designers, engineers, and entrepreneurs to bring their ideas to life with greater efficiency and flexibility. In this article, we will delve into the myriad applications and the limitless potential of 3D printing in manufacturing and design.

The Basics of 3D Printing:

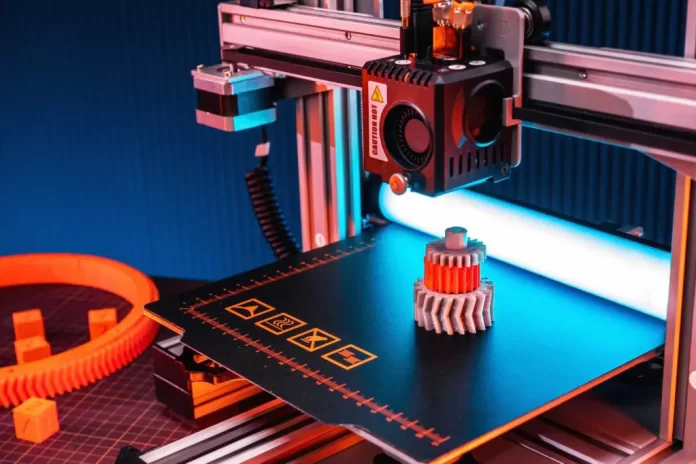

At its core, 3D printing involves translating digital designs into tangible objects through the layer-by-layer deposition of materials. The process begins with the creation of a three-dimensional computer-aided design (CAD) model, which is then sliced into numerous thin cross-sectional layers. These layers serve as a blueprint for the 3D printer, which proceeds to fabricate the object by adding material layer by layer until the final product is complete.

Advantages of 3D Printing in Manufacturing:

Design Freedom: Traditional manufacturing processes often impose limitations on design due to constraints in production techniques. 3D printing, however, allows for unparalleled design freedom, enabling the creation of intricate and complex geometries that were previously unachievable.

Rapid Prototyping: 3D printing facilitates the rapid prototyping process, reducing the time and cost required to create prototypes. This enables designers and engineers to iterate and test their concepts quickly, leading to accelerated product development cycles.

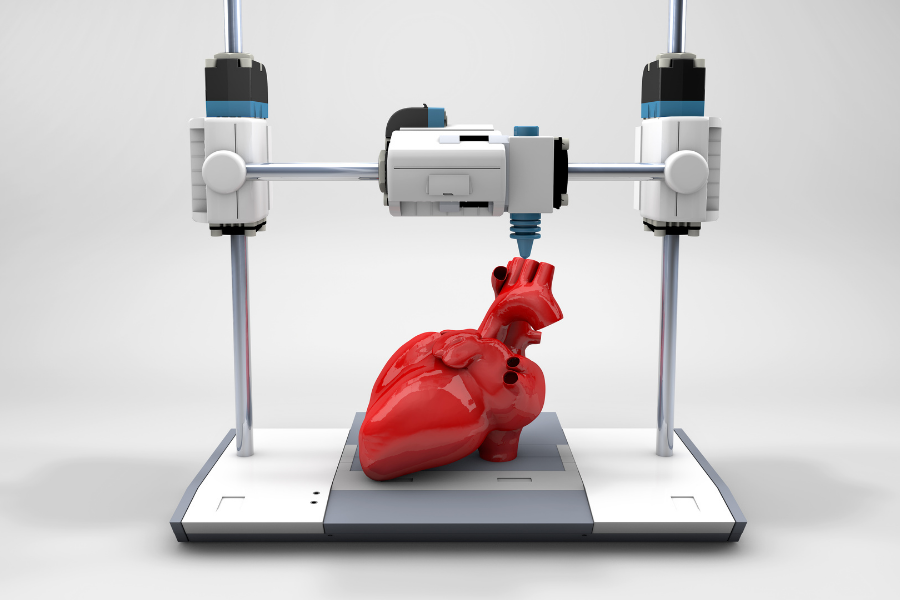

Customization and Personalization: One of the most significant advantages of 3D printing is the ability to create highly customized and personalized products. This technology enables the adaptation of designs to fit individual needs and preferences, revolutionizing fields such as healthcare, where patient-specific prosthetics and implants can be produced.

On-Demand Manufacturing: Traditional manufacturing often involves large-scale production runs, leading to excess inventory and storage costs. 3D printing allows for on-demand manufacturing, enabling the production of items as and when they are needed, reducing waste and inventory costs.

Applications of 3D Printing in Manufacturing and Design:

Healthcare: The healthcare industry has witnessed remarkable advancements through 3D printing. From the production of patient-specific anatomical models for surgical planning to the creation of personalized prosthetics and implants, this technology has improved patient care, surgical outcomes, and the quality of life for many individuals.

Aerospace and Automotive: 3D printing has found significant applications in the aerospace and automotive industries. The ability to create lightweight, complex components with optimized geometries has led to improved fuel efficiency, reduced costs, and enhanced performance in both sectors.

Architecture and Construction: Architects and construction professionals are embracing 3D printing to build intricate and sustainable structures. The technology enables the creation of complex shapes, reduces material waste, and enhances design flexibility, opening up new possibilities in architectural design and construction methodologies.

Consumer Goods: 3D printing is enabling the customization of consumer goods, ranging from fashion accessories to home décor items. Consumers can now personalize products to suit their individual tastes and preferences, providing unique and one-of-a-kind items.

Education and Research: 3D printing has become an invaluable tool in education and research, fostering creativity, innovation, and hands-on learning. It allows students and researchers to visualize abstract concepts, create prototypes, and explore design principles in a tangible and engaging manner.

Future Prospects and Challenges:

As 3D printing technology continues to evolve, its potential in manufacturing and design seems boundless. Researchers are exploring new materials, such as biocompatible polymers and metals, that could further expand the range of applications. Additionally, advancements in multi-material and multi-color printing are unlocking exciting possibilities for complex, multi-functional objects.

However, several challenges must be addressed for 3D printing to reach its full potential. These include the development of faster printing speeds, improved material properties, enhanced quality control measures, and the need for standardized processes and certifications.

Conclusion:

3D printing is ushering in a new era of manufacturing and design, offering unparalleled advantages in terms of design freedom, customization, and rapid prototyping. Its impact spans across various industries, empowering individuals and businesses to innovate, streamline production, and create highly tailored solutions. As the technology continues to advance and overcome its challenges, we can only begin to fathom the limitless potential that 3D printing holds for the future of manufacturing and design.