Over the past few decades, 3D printing technology has emerged as a groundbreaking innovation with the potential to revolutionize the manufacturing and design industries. Also known as additive manufacturing, 3D printing offers a range of possibilities that were once unimaginable. From creating intricate prototypes to producing functional end-use parts, this technology is transforming the way we think about production.

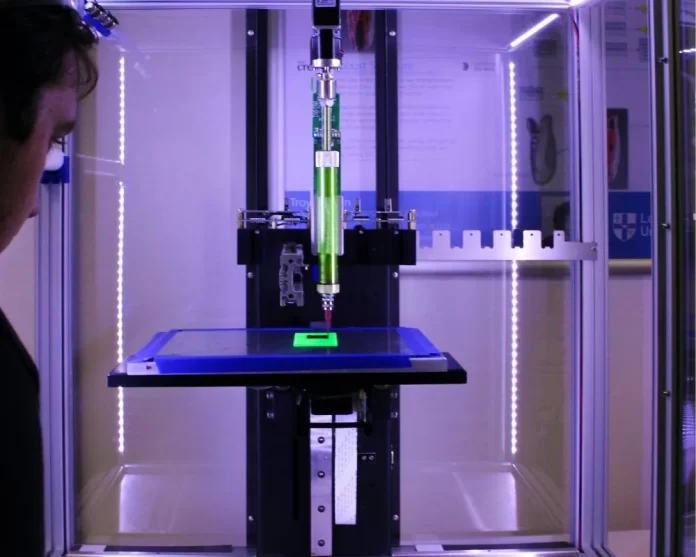

At its core, 3D printing involves the process of creating three-dimensional objects layer by layer, based on a digital design. The process begins with a 3D model, which can be generated using computer-aided design (CAD) software or obtained from existing designs through 3D scanning. The model is then sliced into thin layers, and the 3D printer builds the object layer by layer, fusing materials together to create a solid object.

One of the key advantages of 3D printing is its ability to produce highly complex geometries that would be challenging or even impossible to achieve using traditional manufacturing methods. Traditional techniques like injection molding or subtractive manufacturing often involve removing material or using molds, limiting the shapes and designs that can be produced. With 3D printing, intricate and organic forms can be easily realized, pushing the boundaries of what is aesthetically and structurally possible.

In addition to complex geometries, 3D printing offers unparalleled customization and personalization capabilities. Traditional manufacturing typically involves producing large quantities of identical items, making it difficult to cater to individual preferences or specific requirements. However, 3D printing allows for on-demand production, enabling each item to be unique. This opens up new opportunities for personalized products, custom-fit medical implants, tailored fashion items, and more. The ability to create one-of-a-kind objects without incurring significant costs or time constraints has immense implications for various industries.

Moreover, 3D printing presents a more sustainable alternative to conventional manufacturing practices. Traditional manufacturing often results in substantial waste due to inefficient use of materials and energy. In contrast, 3D printing is an additive process that only uses the necessary amount of material, reducing waste and minimizing environmental impact. Additionally, the localized nature of 3D printing allows for decentralized production, reducing transportation costs and carbon emissions associated with global supply chains.

The versatility of 3D printing extends beyond producing prototypes and customized products. It has the potential to revolutionize industries such as healthcare, aerospace, automotive, and architecture. In the healthcare sector, 3D printing has already made significant strides in creating patient-specific medical models, surgical guides, and even complex organ structures. This technology enables doctors to plan surgeries more accurately, leading to better patient outcomes. It also holds promise for bioprinting, where living cells are used as “ink” to create functional tissues and organs, potentially revolutionizing organ transplantation.

In aerospace and automotive industries, 3D printing enables the production of lightweight, complex parts that reduce fuel consumption and enhance performance. It also facilitates rapid prototyping, allowing engineers to iterate designs quickly and efficiently. Similarly, in architecture, 3D printing enables the creation of intricate building components, reducing construction time and enabling the realization of complex architectural designs.

Despite its tremendous potential, 3D printing still faces some challenges. The technology is continually evolving, and advancements are required to improve print speed, material selection, and cost-effectiveness. However, significant progress has already been made, and with ongoing research and development, these limitations are being addressed.

In conclusion, 3D printing is a transformative technology with the potential to revolutionize manufacturing and design. Its ability to create complex geometries, offer customization and personalization, reduce waste, and enable decentralized production has far-reaching implications across various industries. As the technology continues to mature, we can expect to see even more groundbreaking applications and innovations, shaping the future of manufacturing and design in ways we can only begin to imagine. The era of 3D printing has arrived, and it holds immense promise for a more efficient, sustainable, and creative future.